Sewing Studio manual

1. Industrial sewing machines

1.2. Replacing a needle

Selecting a needle

Check the machine-specific set of needles and select the right needle for your material. Use thicker thread with stronger needles (No. 100–130).

- No. 70 thin materials.

- No. 80 basic needle for most materials.

- No. 90 medium materials.

- No. 100–130 heavy materials.

- Leather needles no. 90–130, the needle tip is knife-like.

- Ball-tip needles, for flexible materials (zig zag machines, overlockers).

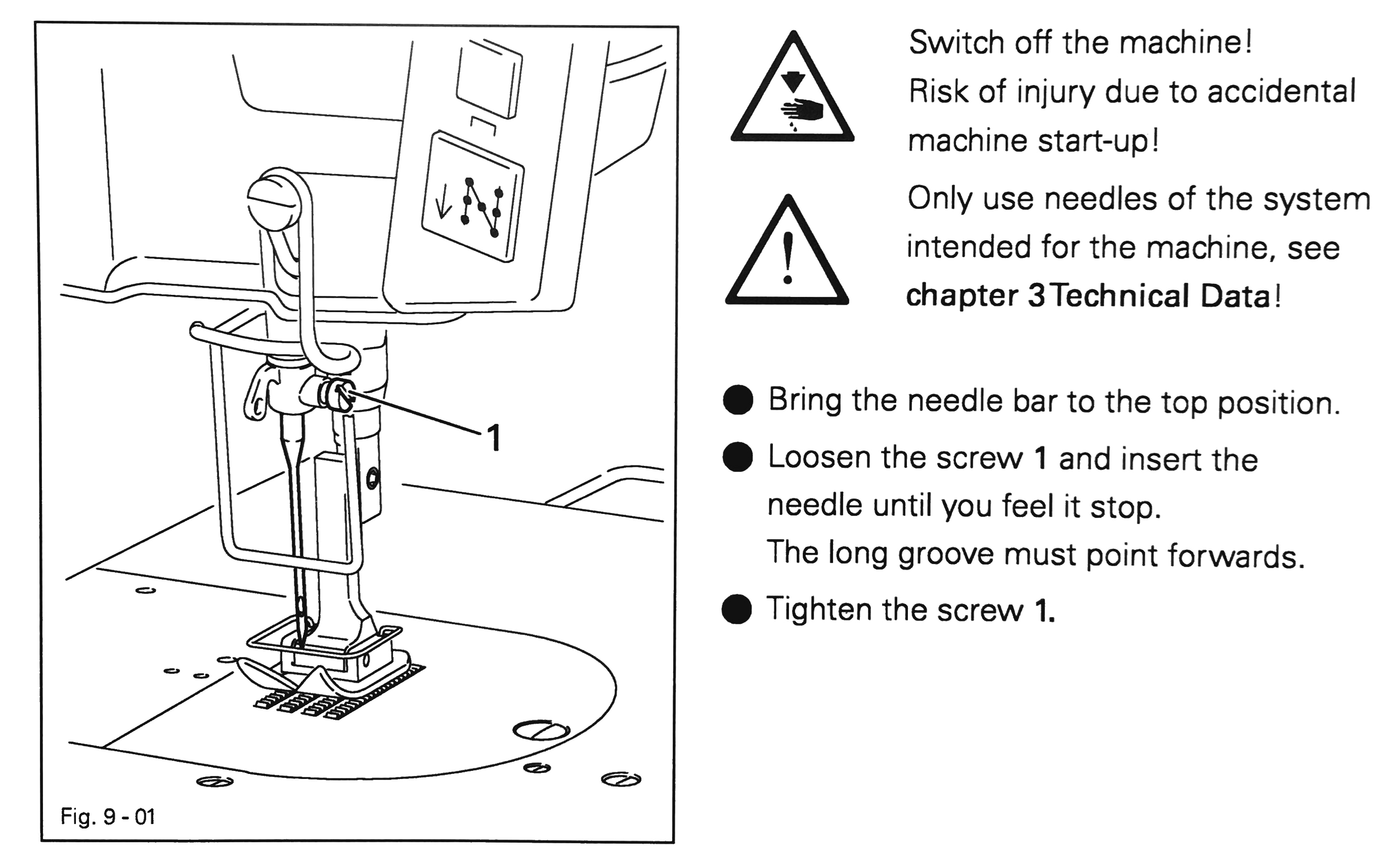

Replacing a needle

The most common cause of skipped stitches is a problem with the needle tip. It is sometimes challenging to spot the damage with the naked eye.

-

Turn off the machine. - Loosen the needle set screw (1), remove the needle, and recycle it into a separate waste container for “blades and needles” in the sewing accessory cabinet.

- Insert a new needle and push upwards until the needle hits the stop (O), tighten the screw.

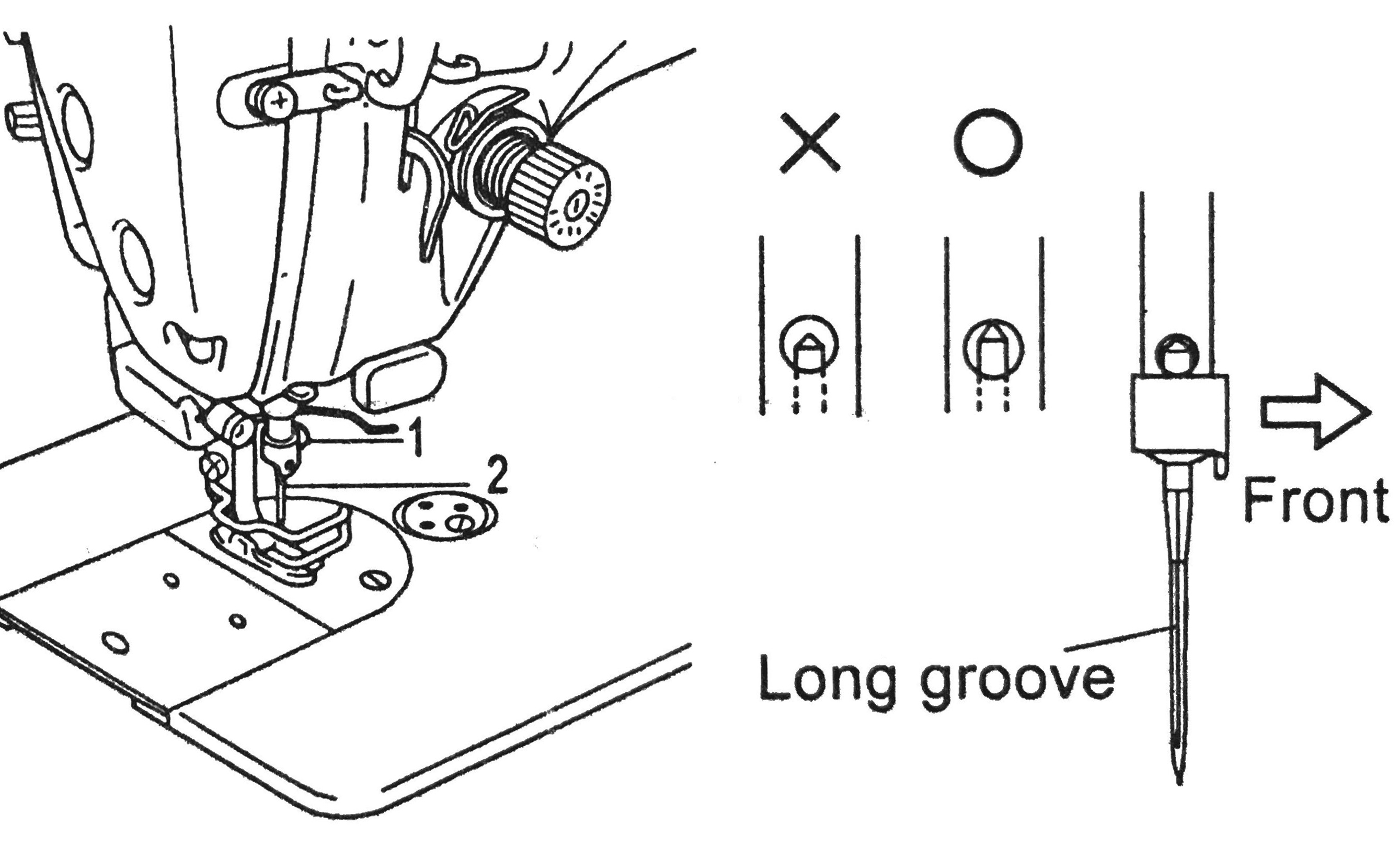

Needle position

The long groove in the needle points in the same direction as the bobbin case. The thread goes into the eye of the needle from the side of the long groove.

- In straight stitch machines, the long groove of the needle points to the left and the thread goes into the eye of the needle from left to right.

- In zigzag machines, the long groove of the needle points to the front and the thread goes into the needle eye from front to back.