Servo test bench

| Site: | MyCourses |

| Course: | KON-C3003 - Mekatroniikan harjoitustyö, Luento-opetus, 10.1.2023-13.4.2023 |

| Book: | Servo test bench |

| Printed by: | Guest user |

| Date: | Friday, 15 November 2024, 4:19 PM |

Description

Demonstration and test device for three different size RC-servos

1. Servo demo device

RC-servo test bench:

- 3 different sized rc-servos

- 3 different test programs

- 2 special servos (continuous & with feedback)

About the project:

An one example of a project documentation

2. Mechanical design

The goal was to build a rigid and clean machine. Here are some examples of manufacturing methods used:

Laser cutting of the polycarbonate frame:

The panels for the box were laser cut from 10mm thick acrylic sheet. The sheet was twice as thick as the maximum cutting thickness of the machine, but the cutting was still successful except for some minor bending of the cuts. Laser cutting provides a clear and good finish to clear plastics. Some deformed cuts had to be milled afterwards. Milling leads to cloudy surfaces, as can be seen on the hole for the LDC screen. Acrylic was chosen because it lets the user also view the inner parts of the device. As a material it is quite heavy and brittle, but it seems to withstand the loads caused by the servos.

Aluminium parts were milled:

Thin aluminium is an easy material to mill and therefore good for novice machinists. For the right parameters and overall safety, asking help from lab staff is highly recommended or even required.

Multiple custom parts were 3D-printed:

Finding the right parameters for the printer may need some iteration, as it can vary even between printers of the same model. For example, with the switch knobs it took four tries to succeed in manufacturing the right dimensions. The 3D-printers (the Ultimakers located in ADD-lab) have a short course which is required before operating the machines. By completing ENG-A1009, Practical Work Training with 3D-printers, you also gain one credit!

Holes were drilled and tapped to the frame:

Polycarbonate has a fairly low melting point, so it may get stuck into the drill flutes and cause damage to the drill bit. Also, making threads requires precision and careful use of the tools. Using screws to assemble the frame allows later disassembly and is way more rigid than hot glue or tape.

3. Hardware

Under the polycarbonate panels of the device, there is quite a lot of electronics:

- Converts the 230V alternating current to 12V direct current.

- Easy to use terminals with proper labels.

- Non-insulated, needs caution.

- Power cord was taken from an old coffee machine.

- Strain relief as shown below was made by printing a clamp inside the device.

- Drops the voltage to 5V for Arduino.

- Needs a circuit board

Arduino microcontroller

- A regular UNO or similar works fine.

- With enough motors, an Arduino with more pins is needed.

- 16 channels -> 16 separate motors

- Uses I2C to communicate with Arduino

Servo motors

Behaviour of the servos is inspected with a help of different sensors:

- Amplify the signal coming from the load cells.

- Placed in a solderable copper plated circuit board.

- HX711 is quite a common example and has a good library.

- Two strain gauges per load cell.

- Cells need calibration.

- Many different maximum load ratings available.

- For measuring the rotational speed of servos.

- Plates with holes were printed and attached to servos. Optical switch detects the holes when the servo rotates. The speed is then counted from the time taken to rotate the certain angle between the holes.

- Need to be positioned precisely.

Optical switch and load cell.

To operate all this, a user interface is needed:

- Connected to Arduino via I2C.

- Common model, available both with or without I2C module.

Buttons and toggle switches

3.1. About rc-servos

General information:

-RC servos (or hobby servos) are actuators designed primarily for radio-controlled vehicles.

-Good for mechanical actuation and controlling.

-The output shaft has a 180 degree turning radius, but the servo can be modified to rotate continuously.

-Receives internal feedback by a potentiometer. The servo limits itself according to the potentiometer signal.

-Arduino has a built-in “servo.h” library that contains the necessary commands.

-Using multiple servos or heavy-duty servos requires an external power source. A few small servos without load can be attached directly to Arduino pins without issues.

-RC servos cost between 1€ to 100€

-Servos are classified by physical dimensions. Other important features include maximum torque, speed and materials used.

Main components:

-Case/outer shell

-Fastening points (or mounting tabs) at sides

-Dc motor

-Operating voltage varies from 5 to 7,4 V. Smaller servos can run with voltages as low as 3,5 V.

-Gearbox

-Increases torque, decreases speed

-Made from plastic or metal

-Physical limiter for turning

-Potentiometer

-Connected to output shaft

-Gives feedback of the servo’s current position, tells the servo’s internal controller when to stop when the control signal changes

-Three (or four) leads

-Voltage, ground, signal, (potentiometer reading)

-Typical hobby level servos have three leads, as potentiometer reading is not needed outside of the servo in most applications

Example specifications:

-4.6 kg, 0.13 sec, 22 g

-4.6 kg -> maximum torque 4.6 kg/cm -> approx. 0.45 Nm

-0.13 sec -> turns 60 degrees in 0.13 seconds

-22 g -> servo’s own mass, approx. 22 grams

Problems:

-Small movements only exert little torque

-Some servos have very unstable mounting tabs

-Vibration

-Cheap servos are not very durable or mechanically robust

Instructions and tips:

projects: https://www.hackster.io/projects/tags/servo?sort=respected

sparkfun tutorial: https://learn.sparkfun.com/tutorials/hobby-servo-tutorial

adafruit tuotrial: https://learn.adafruit.com/adafruit-arduino-lesson-14-servo-motors/overview

futaba rc servo choosing guide: https://www.futabarc.com/servos/servo-wizard.php

continuously rotating servo: https://learn.adafruit.com/modifying-servos-for-continuous-rotation/overview

online store: https://hobbyking.com/en_us/radios-servos/servos.html?___store=en_us

online store: http://fi.eurorc.com/category/18/servot

4. Software

This device includes multiple different sensors, actuators etc., so there are several libraries. Some of them may be helpful for other projects too. Most of the libraries are available on Arduino IDE.

This chapter contains the Arduino code which is used in the device.

4.1. main

/*########## Main program for the servo test bench ##########*/

#include "HX711.h"

#include "inc/operations.h"

#include "inc/interruptFunctions.h"

#include "inc/declarations.h"

#include

/*----------DEFINITIONS AND VARIABLES----------*/ // The rest of the declarations and variables are in declarations.h

/*## Force sensors ##*/

HX711 small_servo_scale(8, 9);

HX711 med_servo_scale(10, 11);

HX711 big_servo_scale(12, 13);

HX711 scales[3] = {big_servo_scale, med_servo_scale, small_servo_scale};

/*## PWM servo driver ##*/

Adafruit_PWMServoDriver servohandler = Adafruit_PWMServoDriver();

/*## Servo info containers ##*/

// Some parts are commented out because of memory shortage

String big_servo_info[7] = {"Turnigy S8166M", "Large", /*"Mass:*/ "154 g", /*"Torque:*/ "33 kg.cm", /*"Speed:*/ "0,21 s/60 deg", "Voltage: 4,8-6 V", "Metal gears"};

String med_servo_info[7] = {"Towerpro MG996R", "Standard", /*"Mass:*/ "55 g", /*"Torque:*/ "9,4-11 kg.cm", /*"Speed:*/ "0,2-0,16 s/60 deg", "Voltage: 4,8-6 V", "Metal gears, digital"};

String small_servo_info[7] = {"Turnigy TG9E", "Micro", /*"Mass:*/ "9 g", /*"Torque:*/ "1,5 kg.cm", /*"Speed:*/ "0,12 s/60 deg", "Voltage: 4,8-6 V", "Plastic gears, analog"};

String continuous_servo_info[7] = {"Fitec FS90R", "Micro", /*"Mass:*/ "9 g", /*"Torque:*/ "1,3-1,5 kg.cm", /*"Speed:*/ "100-300 RPM", "Voltage: 4,8-6 V", "Continuous rotation"};

String feedback_servo_info[7] = {"Datan B2122", "Micro", /*"Mass:*/ "15,81 g", /*"Torque:*/ "1,8 kg.cm", /*"Speed:*/ "0,1 s/60 deg", "Voltage: 4,8-6 V", "Analog feedback"};

/*## Servos ##*/

// For the definition and detailed explanation of type c_servo, refer to operations.h

// General format: c_servo servo = {index, minpos, maxpos, pos, startpos, measure_start, led, arm_length, info};

c_servo big_servo = {3, 190, 585, 450, 450, 470, 8, 4.3, big_servo_info};

c_servo med_servo = {2, 125, 550, 520, 520, 260, 7, 3.0, med_servo_info};

c_servo small_servo = {1, 120, 485, 440, 440, 150, 6, 1.4, small_servo_info};

c_servo continuous_servo = {0, 255, 400, 345, 345, 0, 5, 0, continuous_servo_info};

c_servo feedback_servo = {4, 170, 580, 500, 500, 0, 9, 0, feedback_servo_info};

c_servo servos[5] = {continuous_servo, small_servo, med_servo, big_servo, feedback_servo};

/*## LCD ##*/

LiquidCrystal_I2C lcd(0x20, 16, 2);

/*## Misc ##*/

//uint16_t setpoints[5];

uint16_t average = 0;

//uint16_t reading = 0;

//byte index = 0;

bool startup = true;

/*--------DEFINITIONS AND VARIABLES END--------*/

/*------------------FUNCTIONS------------------*/

/*## Initializations ##*/

// Move each servo to its starting position

void init_servos() {

servohandler.setPWMFreq(60);

for (int i = 0; i < 5; i++) {

servohandler.setPWM(servos[i].index, 0, servos[i].startpos);

}

}

// Set the various pin modes and pullups for the button pins

void init_buttons() {

pinMode(select_next_servo, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(select_next_servo), next_servo, FALLING);

pinMode(select_prev_servo, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(select_prev_servo), previous_servo, FALLING);

pinMode(switch_mode, INPUT);

pinMode(tare_scales, INPUT);

pinMode(toggle_info, INPUT);

digitalWrite(switch_mode, HIGH);

digitalWrite(tare_scales, HIGH);

digitalWrite(toggle_info, HIGH);

}

// Set the calibration factors for each load cell amplifier

void init_scales() {

big_servo_scale.set_scale(big_servo_calib_factor);

med_servo_scale.set_scale(med_servo_calib_factor);

small_servo_scale.set_scale(small_servo_calib_factor);

}

// Initialize pin change interrupts for digital pins 4 to 6

void init_PCint() {

digitalWrite(4, HIGH);

PCMSK2 |= bit (PCINT20);

PCIFR |= bit (PCIF2);

PCICR |= bit (PCIE2);

digitalWrite(5, HIGH);

PCMSK2 |= bit (PCINT21);

PCIFR |= bit (PCIF2);

PCICR |= bit (PCIE2);

digitalWrite(6, HIGH);

PCMSK2 |= bit (PCINT22);

PCIFR |= bit (PCIF2);

PCICR |= bit (PCIE2);

}

// Set the remaining pin modes

void init_misc() {

pinMode(servo_control_pin, INPUT); // Main potentiometer (controls servos)

pinMode(feedback_pin, INPUT); // Potentiometer of the feedback servo

}

/*## Switch to the next servo and/or operation mode and update the LCD accordingly ##*/

void update_selection() {

if (digitalRead(toggle_info) == LOW) curr_mode = 4;

else if (digitalRead(toggle_info) == HIGH) {

if (curr_servo_index > 0 and curr_servo_index < 4) curr_mode = digitalRead(switch_mode);

else if (curr_servo_index == 0) curr_mode = 3;

else if (curr_servo_index == 4) curr_mode = 2;

}

if (ledchange) { // Check whether the active LED should be changed

for (int i = 0; i < 5; i++) {

servohandler.setPWM(servos[i].led, 4095, 0); // Turn off all other LEDs

}

servohandler.setPWM(servos[curr_servo_index].led, 0, 4095); // Turn on the desired LED

ledchange = false;

}

if ((prev_servo_index != curr_servo_index) or startup) { // Check if a change of active servo is queued

move_to_start(servohandler, servos[prev_servo_index]);

prev_servo_index = curr_servo_index;

operation_mode = curr_mode;

prev_mode = curr_mode;

init_view(operation_mode, lcd);

} else if (prev_mode != curr_mode) { // Check if the operation mode has changed (evaluated only if the servo hasn't changed)

operation_mode = curr_mode;

prev_mode = curr_mode;

init_view(operation_mode, lcd);

}

}

/*## Tare all scales ##*/

void tare_all() {

big_servo_scale.tare();

med_servo_scale.tare();

small_servo_scale.tare();

}

/*----------------END FUNCTIONS----------------*/

void setup() {

init_buttons();

init_scales();

init_PCint();

init_misc();

lcd.init();

lcd.backlight();

lcd.print("Servo test bench");

delay(2000);

lcd.clear();

lcd.print("Press 'Tare'");

lcd.setCursor(0,1);

lcd.print("to continue.");

while (true) {

if (digitalRead(tare_scales) == LOW) break;

delay(100);

}

lcd.clear();

lcd.print("Please wait");

servohandler.begin();

tare_all();

init_servos();

for (int i = 0; i < 5; i++) {

servohandler.setPWM(servos[i].led, 0, 4095);

}

delay(1000);

for (int i = 0; i < 5; i++) {

servohandler.setPWM(servos[i].led, 4095, 0);

}

init_view(operation_mode, lcd);

update_selection();

startup = false;

delay(200);

}

void loop() {

update_selection();

if (digitalRead(tare_scales) == LOW and operation_mode == 1) {

lcd.setCursor(0,1);

lcd.print("Zeroing scales ");

tare_all();

lcd.setCursor(0,1);

lcd.print("Scales zeroed ");

delay(1500);

init_view(operation_mode, lcd);

}

/*reading = analogRead(servo_control_pin);

setpoints[index] = reading;

if (index++ > 4) index = 0;

uint16_t sum = 0;

for (int i = 0; i < 5; i++) sum += setpoints[i];

average = sum/5;*/

average = analogRead(servo_control_pin);

if (operation_mode == 0) {

servo_speed_test(servos[curr_servo_index], servohandler, lcd, counter, timer);

} else if (operation_mode == 1) {

switch (curr_servo_index) {

case 1: servo_force_measurement(servos[curr_servo_index], servohandler, lcd, small_servo_scale, average);

break;

case 2: servo_force_measurement(servos[curr_servo_index], servohandler, lcd, med_servo_scale, average);

break;

case 3: servo_force_measurement(servos[curr_servo_index], servohandler, lcd, big_servo_scale, average);

break;

default: break;

}

} else if (operation_mode == 2) {

servo_feedback_handling(feedback_servo, servohandler, lcd, feedback_pin, average);

} else if (operation_mode == 3) {

servo_continuous_drive(continuous_servo, servohandler, lcd, average);

} else if (operation_mode == 4) {

display_info(servos[curr_servo_index], lcd, tare_scales);

}

delay(3);

}

4.2. operations

#include "inc/operations.h"

/*## Functions to execute depending on the current operation mode ##*/

void servo_speed_test(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, volatile uint8_t& counter, volatile unsigned long& end_time) {

unsigned long result, start_time;

if (servo.pos > servo.measure_start) { // Move the servo to the measurement start point

while (servo.pos > servo.measure_start) {

pwm.setPWM(servo.index, 0, servo.pos);

servo.pos--;

delay(3);

}

} else {

while (servo.pos < servo.measure_start) {

pwm.setPWM(servo.index, 0, servo.pos);

servo.pos++;

delay(3);

}

}

delay(500);

if (servo.index < 3) { // Speed test procedure for the small and standard servos

counter = 0;

while ((counter < 2) and (servo.pos < servo.maxpos)) { // Move the servo until the optical switch finds the first hole in the plate

pwm.setPWM(servo.index, 0, servo.pos);

servo.pos++;

delay(7);

}

delay(1000);

start_time = micros(); // Get the start time

pwm.setPWM(servo.index, 0, servo.maxpos); // Move servo to max position

delay(300);

result = (end_time - start_time)/1000; // The plate has two holes, the second of which will have triggered an ISR that updates the value of "end_time"

delay(100);

} else if (servo.index == 3) { // Same procedure as previously, but for the large servo. This servo has the opposite direction of rotation

delay(500); // to the other two.

counter = 0;

while ((counter < 2) and (servo.pos > servo.minpos)) {

pwm.setPWM(servo.index, 0, servo.pos);

servo.pos--;

delay(7);

}

delay(1000);

start_time = micros();

pwm.setPWM(servo.index, 0, servo.minpos);

delay(300);

result = (end_time - start_time)/1000;

delay(100);

}

lcd.setCursor(0,1);

if (servo.index == 3) {

result *= 60;

result /= 32;

} else if ( servo.index == 2) {

result *= 60;

result /= 70;

} else if (servo.index == 1) {

result *= 60;

result /= 75;

}

lcd.print(float(result)/1000); // Display the result (seconds taken for a 60-degree turn, s/60 deg)

lcd.print(" s/60 deg ");

delay(2000);

servo.pos = servo.maxpos;

}

void servo_force_measurement(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, HX711 scale, uint16_t avg) {

static byte update_delay = 19;

float value;

float torque;

uint16_t setpoint = avg;

if (servo.index < 3) servo.pos = map(setpoint, 0, 1023, servo.maxpos, servo.minpos); // Map the received position setpoint (avg) to match the servo's range of motion

else servo.pos = map(setpoint, 0, 1023, servo.minpos, servo.maxpos);

pwm.setPWM(servo.index, 0, servo.pos);

if (update_delay++ >= 20) { // To prevent the LCD from flickering and keep the system responsive (as far as reading input is concerned),

lcd.setCursor(4,1); // the display only updates every 20 function calls.

value = scale.get_units();

torque = servo.arm_length * value;

lcd.print(torque);

lcd.print(" kg.cm ");

update_delay = 0;

}

}

// The following function is only usable for the feedback servo (index 4)

void servo_feedback_handling(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, byte feedback_pin, uint16_t avg) {

static byte update_delay = 19;

uint16_t setpoint = avg;

int feedback_val = analogRead(feedback_pin); // Read the value from the servo's external feedback pin

//feedback_val = map(feedback_val, 0, 1023, servo.minpos, servo.maxpos);

servo.pos = map(setpoint, 0, 1023, servo.minpos, servo.maxpos);

pwm.setPWM(servo.index, 0, servo.pos);

if (update_delay++ >= 20) {

lcd.setCursor(9,0);

lcd.print(servo.pos);

lcd.setCursor(9,1);

lcd.print(feedback_val);

update_delay = 0;

}

}

// The following function is only usable for the continuously rotating servo (index 0)

void servo_continuous_drive(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, uint16_t avg) {

static byte update_delay = 19;

uint16_t setpoint = avg;

servo.pos = map(setpoint, 0, 1023, servo.maxpos, servo.minpos);

pwm.setPWM(servo.index, 0, servo.pos);

if (update_delay++ >= 20) {

lcd.setCursor(9,1);

lcd.print(servo.pos);

lcd.print(" ");

update_delay = 0;

}

}

/*## Function for moving a servo to its starting position ##*/

void move_to_start(Adafruit_PWMServoDriver& pwm, c_servo& servo) {

pwm.setPWM(servo.index, 0, servo.pos);

if (servo.pos < servo.startpos) {

while (servo.pos < servo.startpos) {

pwm.setPWM(servo.index, 0, servo.pos);

servo.pos++;

delay(2);

}

}

else if (servo.pos > servo.startpos) {

while (servo.pos > servo.startpos) {

pwm.setPWM(servo.index, 0, servo.pos);

servo.pos--;

delay(2);

}

}

delay(500);

}

/*## Function for displaying various information about the selected servo ##*/

void display_info(c_servo& servo, LiquidCrystal_I2C& lcd, byte pin) {

static unsigned long timer = millis();

static unsigned long button_delay = millis();

static byte section = 0;

static byte character = 0;

static bool first_print = true;

static byte prev_servo = servo.index;

if (prev_servo != servo.index) {

first_print = true;

section = 0;

character = 0;

prev_servo = servo.index;

}

if (digitalRead(pin) == LOW and millis() - button_delay > 200) { // Checking for a button press (polling, not interrupt). Pressing the button

character = 0; // switches to the next info section (i.e. from servo name to servo category

first_print = true;

if (section++ > 5) section = 0;

button_delay = millis();

}

if (first_print) {

first_print = false;

lcd.setCursor(0,0);

for (int i = 0; i < 16; i++) {

if (i > servo.info[section].length() - 1) lcd.print(" ");

else lcd.print(servo.info[section][i]);

}

timer = millis();

}

if (servo.info[section].length() > 16) { // The following part makes the text scroll after a short delay, but only if the length of the

if (millis() - timer > 2000) { // text exceeds the screen dimensions

lcd.setCursor(0,0);

for (int i = character; i < character + 16; i++) {

if (i > servo.info[section].length() - 1) lcd.print(" ");

else lcd.print(servo.info[section][i]);

}

if (character++ > servo.info[section].length() - 16) {

character = 0;

lcd.setCursor(0,0);

lcd.print(" ");

lcd.setCursor(0,0);

for (int i = 0; i < min(16, servo.info[section].length()); i++) {

lcd.print(servo.info[section][i]);

}

timer = millis();

} else timer = millis() - 1500;

}

}

}

/*## Function for initializing the LCD to match the current operating mode ##*/

void init_view(byte operation_mode, LiquidCrystal_I2C lcd) {

lcd.clear();

lcd.setCursor(0,0);

switch (operation_mode) {

case 0: lcd.print("Speed test: ");

break;

case 1: lcd.print("Torque: ");

break;

case 2: lcd.print("Setpoint: ");

lcd.setCursor(0,1);

lcd.print("Position: ");

break;

case 3: lcd.print("Setpoint: ");

break;

case 4: lcd.setCursor(0,1);

lcd.print("Tare to continue");

default: break;

}

}

4.3. operations header

#ifndef OPERATIONS

#define OPERATIONS

#include

#include

#include

// Struct for handling a servo's information. Positions are in terms of pulse width (0 to 4096)

typedef struct Customservo {

uint8_t index; // PWM output pin number (Adafruit servo shield)

uint16_t minpos; // Minimum position

uint16_t maxpos; // Maximum position

uint16_t pos; // Current position

uint16_t startpos; // Predetermined "safe" initial position

uint16_t measure_start; // Starting position for speed measurement (used only for small, standard, and large servos)

byte led; // PWM output pin number for the servo's LED

float arm_length; // Length of the servo's arm (used only for small, standard, and large servos)

String* info; // List containing the servo's information

} c_servo;

// Function declarations

void servo_speed_test(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, volatile uint8_t& counter, volatile unsigned long& end_time);

void servo_force_measurement(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, HX711 scale, uint16_t avg);

void servo_feedback_handling(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, byte feedback_pin, uint16_t avg);

void servo_continuous_drive(c_servo& servo, Adafruit_PWMServoDriver& pwm, LiquidCrystal_I2C lcd, uint16_t avg);

void move_to_start(Adafruit_PWMServoDriver& pwm, c_servo& servo);

void display_info(c_servo& servo, LiquidCrystal_I2C& lcd, byte pin);

void init_view(byte operation_mode, LiquidCrystal_I2C lcd);

#endif

4.4. declarations header

#ifndef DECLARATIONS

#define DECLARATIONS

/*## Button pins ##*/

#define select_next_servo 2

#define select_prev_servo 3

#define tare_scales 0

#define switch_mode 1

#define toggle_info 7

/*## Inputs ##*/

#define servo_control_pin A0

#define feedback_pin A1

/*## Servos ##*/

#define first_servo 0 // Indices correspond directly with the Servo Shield servo connection points

#define last_servo 4

volatile uint8_t curr_servo_index = 2; // First servo to activate, in this case the middle servo

volatile uint8_t prev_servo_index = 2;

/*## Misc ##*/

volatile bool ledchange = true; // Indicates whether the active LED should change

volatile unsigned long timer;

volatile uint8_t counter = 0;

byte operation_mode = 1; // 0 for speed test, 1 for force measurement, 2 for feedback servo, 3 for continuous servo, 4 for info screen

byte curr_mode = 1;

byte prev_mode = curr_mode;

float big_servo_calib_factor = -211330; // The calibration factors must be verified with a separate program.

float med_servo_calib_factor = -206420; //

float small_servo_calib_factor = -209240; //

#endif

4.5. interrupts header

#ifndef INTERRUPT_FUNCTIONS

#define INTERRUPT_FUNCTIONS

#include "declarations.h"

/*## Interrupt service routines used for switching between servos ##*/

void next_servo() {

static unsigned long last_interrupt_time_1 = 0;

unsigned long interrupt_time = millis();

if (interrupt_time - last_interrupt_time_1 > 200) { // This part is for debouncing the buttonpress. Debouncing is necessary

if (curr_servo_index < last_servo) curr_servo_index++; // to prevent multiple calls to this ISR (interrupt service routine)

last_interrupt_time_1 = interrupt_time; // with one buttonpress.

ledchange = true; //

}

}

void previous_servo() {

static unsigned long last_interrupt_time_2 = 0;

unsigned long interrupt_time = millis();

if (interrupt_time - last_interrupt_time_2 > 200) {

if (curr_servo_index > first_servo) curr_servo_index--;

last_interrupt_time_2 = interrupt_time;

ledchange = true;

}

}

/*## Interrupt service routine (pin change) ##*/

ISR (PCINT2_vect) { // This ISR is used by the optical switches when performing a speed test

timer = micros();

counter++;

}

#endif

5. Project documentation

Servo test bench

Project documentation

Contents

Introduction

The device

General design

Electronics

Electrical system and wiring

Microcontroller

Servos

Sensors

Mechanical design

Assembly

User interface

The program

Project analysis

Arrangement

Limitations of the design

Encountered problems

Possible future development

Appendix

3D-models

Program files

Parts list

1. Introduction

The servo test bench is a device that demonstrates the capabilities and features of different hobby-grade servos. The main goal is to provide a first impression of servos to people who have never seen one before and give some perspective into the strengths, weaknesses, and overall capabilities of servos. The servos used are typical for school projects as the goal is also to visualize the movement of the servos and act as an example of a possible project.

2. The device

2.1 General design

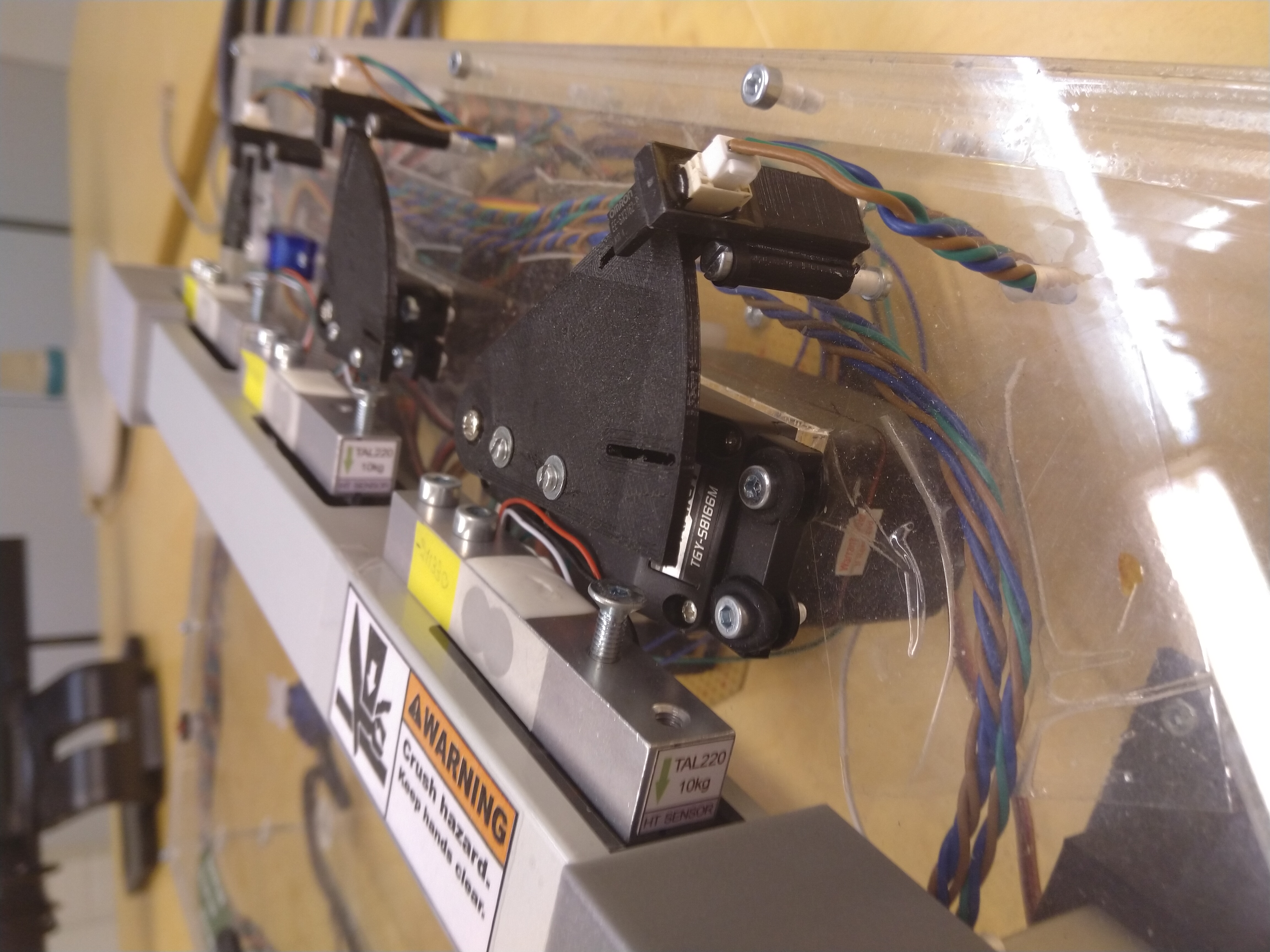

The device features seven different hobby-grade servos – five operational ones and two with a visible cross section. The servo cross sections provide a view of the internal components commonly found in servos. For the sake of contrast, one cross section features a digital metal-geared servo, the other an analog plastic-geared one. Three of the functioning servos, a micro, standard, and large servo, are mounted adjacent to load cells for torque measurement and optical switches for determining the angular velocity. The other two, a servo with external feedback and a continuously rotating servo, are not mounted alongside any sensors, because they demonstrate their specific features.

To enhance the learning experience, the device has a simple interactive user interface that displays information about the active servo and allows the user to control certain features, like selecting between servos and operating modes, and turning servos manually.

2.2 Electronics

2.2.1 Electrical system and wiring

The main power source for the device will be an AC/DC-converter with an output of 12 volts. The converter will supply power to the controller and the accompanying servo shield. The controller accepts an input voltage of 7-12 V, but the shield requires 5-6 V, therefore additional voltage regulation is necessary. To drop the voltage down from 12 to 5-6 volts, a DC/DC switch-mode converter is used. When designing a power distribution system, it is vital to ensure correct polarity.

To facilitate maintenance and keep the numerous wires in order, the wires of the components on the lid of the device are grouped into headers: LEDs in one, load cells in another, and the rest in a third.

The following wiring diagram describes where each header pin should be connected:

A note on the markings: the capital letters A and D signify Arduino analog and digital pins respectively, and the capital letter S signifies the servo connection points on the Adafruit servo shield. All the servo connection points include three pins: a signal output (PWM), operating voltage (+), and ground (GND). As can be seen from the schematic, some pins are connected together, so that only one wire is needed to connect them to, for example, ground.

When connecting the 34-pin header to the board, please make sure that the red marker is facing away from the Arduino. The LED header (pins L1-L6) should be connected so that the blue wire of the header is on the same side as the blue wire of the board.

The next schematic describes the overall wiring (excluding headers):

2.2.2 Microcontroller

The central processor of the servo test bench is an Arduino Uno. This is coupled with a servo shield that enables controlling servos using the I2C bus, thus liberating standard I/O pins for other uses. Another function of the servo shield is to provide power to the servos; the Arduino itself cannot provide enough current through its 5 V pin to operate the servos and all the other peripherals simultaneously.

2.2.3 Servos

The functional servos used in the device:

Make/model | Size category | Mass (g) | Torque (kg.cm) | Operating speed (s/60°) | Operating voltage (V) | Additional information |

Turnigy TG9e | Micro | 9 | 1,5 | 0,12 | 4,8-6 | Plastic gears, analog |

Towerpro MG996R | Standard | 55 | 9,4-11 | 0,20-0,16 | 4,8-6 | Metal gears, digital |

Turnigy S8166M | Large | 154 | 33 | 0,21 | 4,8-6 | Metal gears |

Datan B2122 | Micro | 15,81 | 1,8 | 0,1 | 4,8-6 | Analog feedback |

Fitec FS90R | Micro | 9 | 1,3-1,5 | 100-130 RPM | 4,8-6 | Continuous rotation |

Where the torque or speed is indicated as a range, the minimum value is achieved with the lowest operating voltage and maximum with the highest.

The cross sectioned servos:

Make/model | Size category | Mass (g) | Max. torque (kg.cm) | Operating speed (per 60°) | Operating voltage | Additional information |

H-king HK 15298 | Standard | 66,4 | 8 | 0,12 | 4,8-7,4 | Brass gears, digital |

GWServo S03TXF | Standard | 46 | 5 | 0,21 | 4,8-6 | Plastic gears, analog |

2.2.4 Sensors

The array of sensors consists of three load cells capable of measuring forces up to 98 N (the weight of a 10 kg object) and three optical switches for measuring the angular velocity. An optical switch has an emitter that sends a beam of light to the receiver lens, and whenever something breaks the beam, the electrical output signal of the switch will change. This can be used to determine the angular velocity of the servos: the three servos have plates the shape of circular sectors attached to their arms. The plates have two narrow holes in them, one near the first edge of the sector and another near the next edge (see image below). When the servo turns, the optical switch will detect when each holes passes through the beam, and by measuring the time between detecting the holes, we can determine the angular velocity of the servo.

The angular velocities are displayed in time taken for a 60-degree turn (s/60 deg) and the torque is displayed in kg cm (1 kg mass at 1 cm distance, analogous to Nm).

2.3 Mechanical design

2.3.1 Assembly

Servos with a cross section view were created by disassembling servos and grinding the housings with a belt sander.

The board for load cell amplifiers and general ground/current rails. Pins and resistors were soldered into place and amplifiers were fastened with bolts and nuts.

Connectors for wiring before and after assembly. To achieve easier assembly and disassembly, pin connectors were used.

Button inserts were 3D-printed. The power cord is recycled, as well as the main power switch.

The panels for the box were laser cut from 10mm thick acrylic sheet. The sheet was twice as thick as the maximum cutting thickness of the machine, but the cutting was still successful except for some minor bending of the cuts.

Due to errors with drilling holes at wrong locations, some of the holes had to be filled with plastic screws. The screws were inserted to the holes, then cut to length and new holes drilled and tapped right next to the old ones.

The beam for load cells was milled to the right shape.

2.4 User interface

The user interface consists of three buttons, a three-position switch, a potentiometer, five LEDs, and a liquid crystal display. The switch is used for choosing between the three main operating modes: torque measurement, speed test, and info display. The potentiometer is used for controlling the servos. If one of the normal servos (large, standard, or small) is chosen, the potentiometer only works in torque measurement mode. If one of the special servos (continuously rotating or feedback servo) is chosen, the potentiometer works while not in info display mode. The three buttons are used for switching between servos and zeroing the force sensors. The selected servo is indicated by turning on the corresponding LED. During operation of the device, various information will be displayed on the LCD. For example, in force measurement mode, the current reading will be shown. When the feedback servo is chosen (while not in info display mode), the screen will display the current setpoint (the target position of the servo) and the value from the servo’s internal potentiometer (essentially the actual position of the servo). Each button and switch has a label next to it describing its main purpose shortly.

2.5 The program

The program is divided into modules to facilitate editing and improve readability. Most of the function declarations and descriptions are in separate source files. The program incorporates the following pre-made libraries: Adafruit PWM Servo Driver, HX711, and LiquidCrystal I2C.

The main loop consists of two main phases: first phase checks whether the user has queued a change of servo or operation mode, and switches the current operation mode to match. This information will be necessary in the second phase, where the program calls a specific function based on the operation mode. For example, if the user has selected the standard rc servo and torque measurement, the program will receive user input through the potentiometer and display the value produced by the corresponding load cell. There are a total of five different operation modes, two of which (torque measurement and speed test) are only usable with the normal rc servos. The third mode is the info display mode and the two remaining ones are reserved for the continuously rotating servo and the servo with external feedback. In their respective modes, the latter servos will receive user input.

The program defines endpoints to the range of motion of each servo. This prevents the servos from causing unwanted collisions and damage. In addition, whenever the user switches between servos, the current servo will move back to a safe position before the next servo is activated.

The program files are presented in their entirety in section 4.2.

3. Project analysis

3.1 Arrangement

The project was assigned to develop teaching methods in mechatronics. The team working with the project consisted of three research assistants from Aalto university, which was also responsible for the funding.

3.2 Limitations of the design

To fit to its purpose, the device had to be compact so it could be easily transported and stored. The weight had to be limited so the device could be handheld. Another requirement was that the visualisation of the device had to be clear and as much of the construction visible as possible. For the sake of simplicity and ease of use, the test bench is a standalone unit with no customizable features or connections.

3.3 Encountered problems

-Number of pins in Arduino uno (barely enough)

-Wiring differences between load cells and amplifiers

-connectors to optical switches are small and difficult to assemble properly

-servo behaviour with low voltages

-laser cutting materials exceeding the maximum thickness produces skewed cuts

-correct positioning for the photosensors

-The LCD flickers and doesn't show the entire text when the servo bench starts up. Switching to another view and back stops the behaviour.

-the teeth of small servo’s shaft broke when testing

3.4 Possible future development

Possibilities in developing the device can be divided to two aspects, adding more functions in device itself and building more similar devices for demonstrating sensors and actuators. It is also possible to add some IoT in form of ways of communication for example to students mobile devices.

4. Appendix

4.1 3D-models

4.2 Program files

4.3 Parts list

No. | Part | Qty. |

1 | Arduino Uno | 1 |

2 | Adafruit 1411 Servo Shield | 1 |

3 | Turnigy TG9e Servo | 1 |

4 | Towerpro MG996R Servo | 1 |

5 | Turnigy S8166M Servo | 1 |

6 | Datan B2122 Servo | 1 |

7 | Fitec FS90R Servo | 1 |

8 | H-king HK 15298 Servo | 1 |

9 | GWServo S03TXF Servo | 1 |

10 | DFRobot DFR0063 LCD Display | 1 |

11 | Sparkfun SEN-13879 Amplifier | 3 |

12 | Sparkfun SEN-13329 Load Cell | 3 |

13 | Omron EE-SX3162-P2 Optical Switch | 3 |

14 | Resistor, 220 Ω | 1 |

15 | Resistor, 12 kΩ | 2 |

16 | LED, red | 5 |

17 | Switch, button (Normally open) | 3 |

18 | Switch, toggle | 1 |

19 | Potentiometer | 1 |

20 | Mean Well LRS-50-12 Power Supply | 1 |

21 | GE NSR003A0X4Z DC-DC Converter | 1 |

22 | Wires and connectors | - |