CHEM-E4106 - Electrochemistry D, Lecture, 9.1.2023-21.2.2023

Kurssiasetusten perusteella kurssi on päättynyt 21.04.2023 Etsi kursseja: CHEM-E4106

Kirja

9. Electrochemical energy conversion

9.3. Secondary batteries

Like primary battery chemistries, a number of different secondary batteries are available, and new chemistries are frequently introduced in scientific journals. Moreover, the chemistries are similar to those in primary batteries but the secondary batteries have been designed for re-charging. They are therefore more complex in structure and typically have lower specific energies and energy densities than corresponding primary battery chemistries.

For secondary batteries, the nomenclature of the electrodes differs from the conventionally used anode and cathode. Instead of these terms, the negative and the positive electrode are used. This originates from the fact that during discharging the electrode at the lower potential functions is an anode but while charging it is a cathode. The situation is naturally opposite for the electrode with higher operation potential.

9.3.1 Lead acid battery

The first commercially available battery, the lead acid battery, was invented in the mid-1850, but significant technology improvements have been made since those days. This device is an economical choice for applications where weight is not critical. The affordable price results from low-priced and easily available raw materials and relatively simple fabrication methods. These batteries serve as uninterrupted power systems (UPS) to prevent critical power failure in stationary applications, for example in mobile phone repeater towers, internet hubs and hospitals. Despite their moderate energy density, lead acid batteries are also used as starter batteries in vehicles because they enable high power delivery during discharging, have a low self-discharge rate and are able to operate at low and even subzero temperatures.

Lead acid batteries designed for different application have similar chemistry but differ in technical implementation. For example, the design of the electrodes varies as well as the impregnation of cells with the electrolyte. In general, starting batteries requiring high power delivery, but no deep cycling, have thinner electrodes and are therefore lighter weight than batteries developed for deep cycling. The electrolyte is impregnated in X or gelled for mobile applications in particular.

As can be inferred from the name, lead is used in the both electrodes and concentrated sulfuric acid, approximately 37 vol% or 6-12 mol dm−3 as the electrolyte. Because of the slow water reaction kinetics on the lead-based electrodes, a high operation voltage (for an aqueous system) ranging from 2.15 V (fully charged) to 1.98 V (discharged battery) is obtained. During discharging, sulfuric acid is consumed and water formed, gradually diluting the electrolyte. This, in combination with the formation of lead sulfate, leads to an increase in the internal losses of the battery as the conductivity of both the electrodes and the electrolyte decrease and diffusion overpotentials increase.

The detailed reaction mechanism is very complex but it can be simplified with the following equations:

Negative

electrode: Pb(s) + SO42-(aq)

PbSO4(s)

PbSO4(s)

Pb(s) + H+(aq) + HSO4−(aq)

PbSO4(s) + 2H+(aq) + 2e−

PbSO4(s) + 2H+(aq) + 2e−

Positive

electrode: PbO2(s) + 4H+(aq)

+ SO42−(aq) + 2e−  PbSO4(s)+ 2H2O(l)

PbSO4(s)+ 2H2O(l)

PbO2(s) + HSO4−(aq)

+ 3H+(aq) + 2e−  PbSO4(s) + 2H2O(l)

PbSO4(s) + 2H2O(l)

Net

reaction: Pb + PbO2

+ 2H2SO4  2PbSO4(s) + 2H2O(l)

2PbSO4(s) + 2H2O(l)

Pb

+ PbO2 + 2H+ + 2HSO4−  2PbSO4(s) + 2H2O(l)

2PbSO4(s) + 2H2O(l)

In addition to these reactions, water electrolysis and the formation of H2 and O2 take place via side reactions.

9.3.2 Lithium ion battery

The lithium ion battery (LIB) has rapidly become the most popular battery in portable applications since it was introduced at the beginning of 1990s. These batteries have also been adopted as power sources in electric and hybrid vehicles and for peak power leveling in systems based on intermittent renewable energy. A high energy density combined with a relatively high power density has enabled them to achieve rapid success. LIBS have the downside that as they are rich in energy and contain a flammable electrolyte (LiF6P in a mixture of organic carbonates), large amounts of energy can be release if they are misused or in the case of a factory defect. In order to minimize the risk of of dangerous thermal runaway, each LIB is equipped with an electronic battery management system (BMS) that monitors its state and controls its charging.

Unlike other batteries, LIBs cover several different chemistries giving different characteristics to the batteries. In the first batteries, layered LiCoO2 was used for positive electrodes, and this material is still used in some devices for portable applications. For larger batteries LiCoO2 has been replaced with less expensive mixed oxides such as LiNixMnyCo(1-x-y)O2 and LiNixAlyCo(1-x-y)O2 with rather similar characteristics to LiCoO2. Yet another compound, LiFePO4 is considered a safe alternative with a longer cycle life. However, this chemistry makes a battery that has a lower energy density due to its lower operating voltage and a relatively low lithium ion storage capacity.

Since the first commercial LIBs, graphite has been the most popular negative electrode material. Li4Ti5O12 has been introduced as an alternative for applications that require a long cycle life and high charging rates but can accept the lower intrinsic energy density.

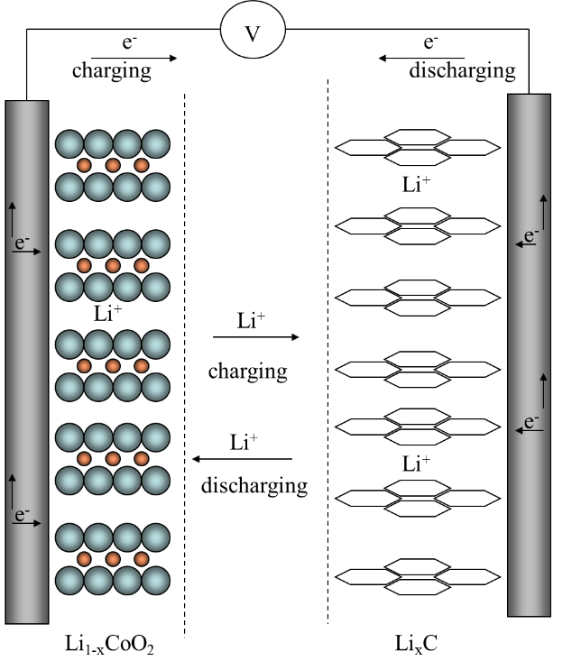

A scheme of the LIB operation is given in Figure 9.5. All the electrode materials set out above are based on the reversible intercalation reaction of the lithium ion in the lattice of the electrode material. It is concomitant with the change of the oxidation state of either of lithium (in graphite) or the transition metal in the host compound. For example, for the C|LiCoO2 chemistry these reactions are as follows:

Negative

electrode: C6 + x Li+

+ x e−  LixC6, x ≤ 1 Eo = 0.05-0.25 V vs. Li|Li+

LixC6, x ≤ 1 Eo = 0.05-0.25 V vs. Li|Li+

Positive

electrode: LiCoO2  Li1-x CoO2 + x Li+ + x e− Eo = 3.0-4.5 V vs. Li|Li+

Li1-x CoO2 + x Li+ + x e− Eo = 3.0-4.5 V vs. Li|Li+

Net

reaction: LiCoO2

+ C6  LixC + Li1−x CoO2

LixC + Li1−x CoO2

Figure 9.5. Operation principle of a LIB with LiCoO2 and C electrodes.

In commercial batteries, organic solvent-based electrolytes are used where LiPF6 serves as the charge carrier. The mixture typically consists of organic carbonates such as dimethyl carbonate, diethyl carbonate and ethyl methyl carbonate. The use of an organic electrolyte that has a higher electrochemical window than water enables the high voltage of the LIB, and the high energy density.