CHEM-E4106 - Electrochemistry D, Lecture, 9.1.2023-21.2.2023

This course space end date is set to 21.04.2023 Search Courses: CHEM-E4106

Kirja

9. Electrochemical energy conversion

9.4. Fuel cells and flow batteries

Fuel cells enable environmentally friendly energy conversion of chemical energy into electricity with high efficiency of up to 83%. Although fuel cells are technologically viable, their high price hinders their adoption for a wider use. In addition to their mass manufacturing, materials development is a key problem to overcome.

Traditionally, fuel cells have been classified into different categories based on the electrolyte. Here, we introduce the polymer electrolyte fuel cell (PEFC) operating at low temperatures, and the high-temperature device, solid oxide fuel cell (SOFC). In the both devices, atmospheric air is often the oxidant. PEFCs mainly use hydrogen as the fuel although different alcohols and other small organic molecules have also been considered. Because of the higher operating temperature, an SOFC can also use synthetic gas, natural gas or biogas.

9.4.1 Polymer electrolyte fuel cell

Polymer electrolyte (membrane) fuel cells (PE(M)FC) have good energy density and can operate at a relatively low temperature range. They therefore provide an option for mobile applications such as electric vehicles and mobile phone chargers. However, they can be scaled up to serve as (local) stationary energy conversion units producing both heat and power, so they are also used for back-up power and auxiliary power unit applications.

The name PEMFC originates from the cation exchange membrane which serves as the solid electrolyte. The most commonly used membrane is Nafion®, a highly acidic material consisting of a perfluorinated polymer backbone with flexible sidechains containing ether linkages and terminal sulfite groups. Protons in these groups must be hydrated in order for the material to transfer protons (from the anode to the cathode). Consequently, operation is limited to the temperature range of liquid water.

Two half-reactions, hydrogen oxidation (HOR) and oxygen reduction (ORR), take place in a fuel cell. Both of these reactions are electrocatalytic i.e. their rates and mechanisms depend significantly on the electrode materials selected. Because of the acidic environment and relatively low operation temperatures, noble metal catalysts are needed to achieve reasonable reaction rates. The following reactions take place in acidic media:

anode:

H2  2 H+ + 2e− Eo = 0.00 vs. SHE

2 H+ + 2e− Eo = 0.00 vs. SHE

cathode:

O2 + 4 H+

+ 4 e−  2 H2O Eo = 1.23 vs. SHE

2 H2O Eo = 1.23 vs. SHE

Due to the high price of these catalysts, alternative catalyst materials and alkaline membrane-based technologies are under development.

9.4.2 Solid oxide fuel cell

Solid oxide fuel cells (SOFC) operate at high temperatures of 500-1,000oC to enhance conductivity of the ceramic electrolyte which is often yttria-stabilized zirconia (YSZ). Because of the high operation temperature and flexibility in the selection of the fuel, SOCFs are an appropriate choice for continuously operating stationary energy conversion systems. Moreover, the high operation temperature enhances electrochemical reactions, and no noble metal catalyst is needed to achieve appropriate reaction rates. Materials such as CoZrO2 or NiZrO2 cermet can serve as an anode while the Sr-doped LaMnO3 cathode is often used. In addition to appropriate functional properties, attention must be paid to matching thermal expansion coefficients when selecting the materials.

Using hydrogen as a fuel following reactions take place:

anode: H2

+ O−  H2O

+ e− Eo = 0.00 vs. SHE

H2O

+ e− Eo = 0.00 vs. SHE

cathode: O2

+ 2 e−  2 O- Eo = 0.00 vs. SHE

2 O- Eo = 0.00 vs. SHE

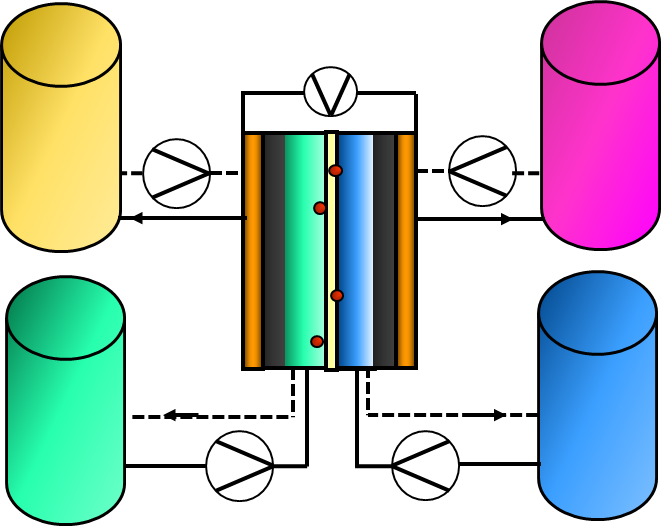

9.4.3 Vanadium flow battery

A flow battery is kind of an intermediate between a battery and a fuel cell. In flow batteries, redox reactions take place in the reactor-type fuel cell but reactants are fed to the electrodes from external containers. A total of four containers is needed as depicted in Figure 9.6. Two of them contain reduced and oxide forms of the electrolyte fed to positive electrodes while the other pair enclose the respective electrolytes for the negative electrolyte. The flow direction is opposite during charging and discharging. The capacity of the system can therefore be adjusted by changing the size of the containers.

Figure 9.6. Construction of a flow battery.

Like in ordinary batteries, potential chemistries suitable for redox flow batteries are, in principle, unlimited. Vanadium flow batteries (VFB) are the only commercially available flow battery; their reactions are given here as an example. The forward direction corresponds to discharging and the backward direction to charging of the VFB.

negative

electrode: V3+ + e−

V2+ Eo = -0.26 vs. SHE

V2+ Eo = -0.26 vs. SHE

positive

electrode: VO2+ + H2O

VO2+ + 2 H+ +

e− Eo = 1.00 vs. SHE

VO2+ + 2 H+ +

e− Eo = 1.00 vs. SHE

net reaction: V3+ + VO2+ + H2O  V2+ + VO2+ + 2 H+

V2+ + VO2+ + 2 H+

Because of their bulky size, flow batteries are suitable for stationary energy storage applications. The electrodes must be made of conductive material enabling the reactions to occur, while a semi-permeable membrane enabling ion transport from one electrode to the other separates the catholyte and anolyte. For example, the in case of VFB discharge, protons are transported from the positive electrode to the negative one. Crossing of the vanadium species between catholyte and anolyte should, however, be avoided. Developmental challenges are related to the electrolyte price and abundancy, as well as to overall system costs. In addition to the VFB, zinc-bromine and sodium-sulfur flow batteries have also been studied, but they have suffered from stability problems.