OK7 Costume Workshop

Ompelimon käsikirja

Suorituksen vaatimukset

Tutustut teollisten ompelukoneiden langoitukseen ja asetusten säätämiseen sekä silityspisteen käyttöön. Ohjevideot (5) opastavat teollisen ompelukoneen ja saumaajan käytössä sekä säätämisessä. Huom! Avaa kirjan sisällysluettelo oikean yläkulman mustasta nuolesta "Avaa lohkot".

YLEISOHJEET

- Valitse kone käyttötarkoituksen mukaan (kts. laitekuvaukset).

- Ota kone pois päältä puolaa/ neulaa vaihtaessasi sekä langoitusta tarkistaessasi.

- Silmä- ja sormisuoja on pidettävä aina paikoillaan.

- Koneet ovat äärimmäisen harvoin rikki, yleensä kyse on langoituksen ongelmista tai neulan kunnosta. Ole kärsivällinen ja yritä selvittää ongelma.

1. Teolliset ompelukoneet

1.1. Puolaus (video)

Puolauslaitteen paikka on koneen päällä tai sivussa.

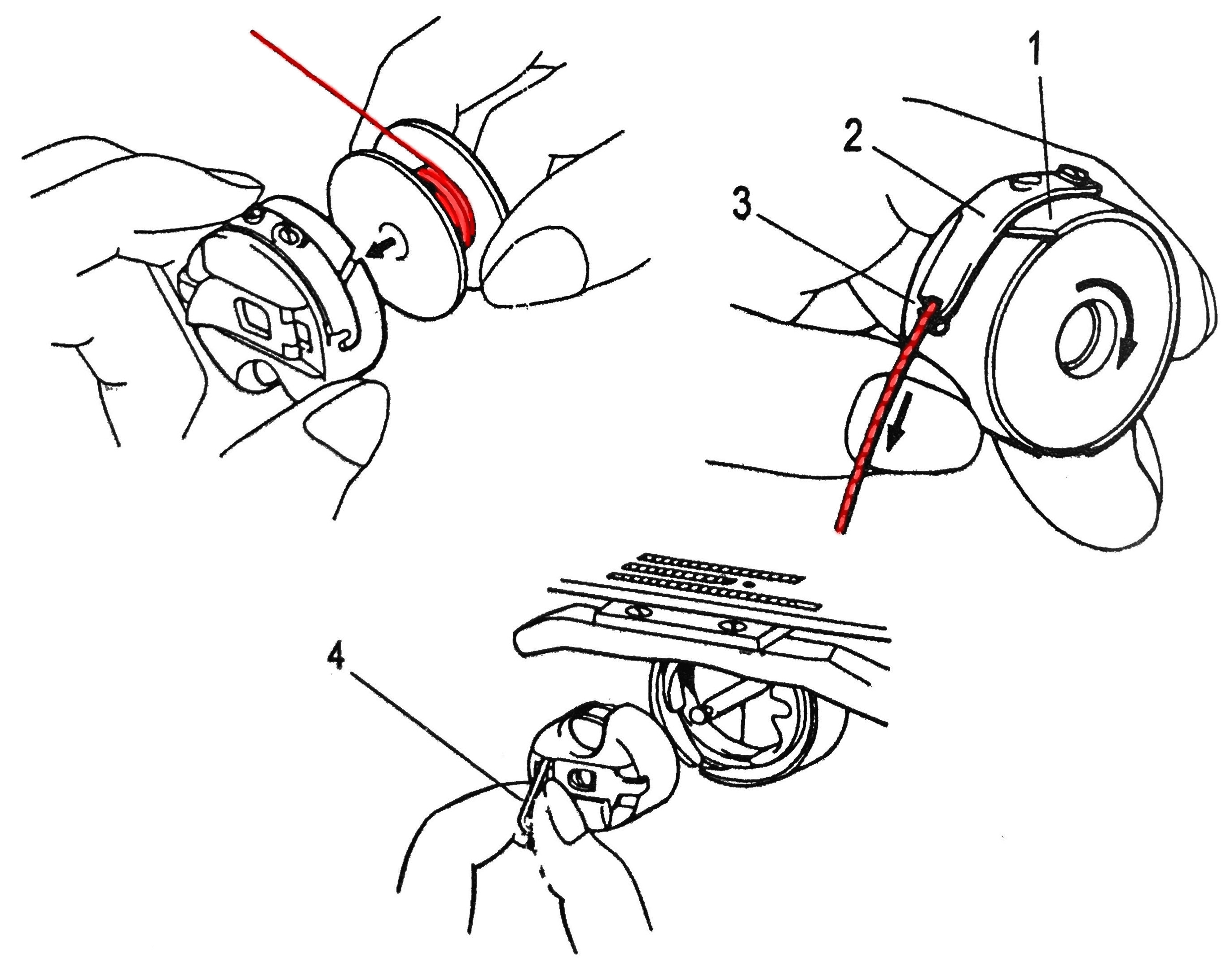

Puolaus:

- Aseta puola puolauslaitteeseen (1).

- Langoita kuvan mukaisesti, tarkista että lanka menee kaikista ohjaimista ja on kiristyslevyjen välissä.

- Kierrä lankaa muutama kerta tiukasti puolan ympärille (2).

- Paina lukitusvipu (3) puolaa vasten ja vedä langanpää leikkuriin (4).

- Voit puolata samaan aikaan ommeltaessa TAI erikseen ilman kangasta, jolloin:

- Poista puola puolakotelosta sekä lanka neulansilmästä, nosta paininjalka manuaalisesti ylös .

- Puolaus loppuu automaattisesti kun puola on täynnä.

Puolan asettaminen puolakoteloon:

- Puolakotelo sijaitsee joko koneen vasemmalla sivulla tai suoraa edessä (siksak-koneet).

- Puolan pyörimissuunta on myötäpäivään.

- Aseta puola koteloon ja ohjaa lanka kuvan osoittamalla tavalla (1-3).

- Aseta puola koneen puolakoteloon vapauttamalla pieni vipu (4).

- Varmista, että puola on lukittunut paikoilleen.

- Lankaa ei tarvitse erikseen nostaa käsipyörällä näkyviin.