MUO-E1042 - Printed Fabrics Studio, Lecture, 24.10.2022-11.11.2022

This course space end date is set to 11.11.2022 Search Courses: MUO-E1042

Info

Printing bases

Printing bases must be hydrophilic, fabrics that are prepared for dyeing and printing will work certainly.

- 100 % CO

- 50/50 % CO/PES

- silk and viscose

Other printing bases:

Printing is also possible for other natural fibers, such as wool, and primed polyester. Please check the suitability of your fabric before printing with the workshop master and, if necessary, with a test print.

Media thickness

- up 25 mm

Printing plates

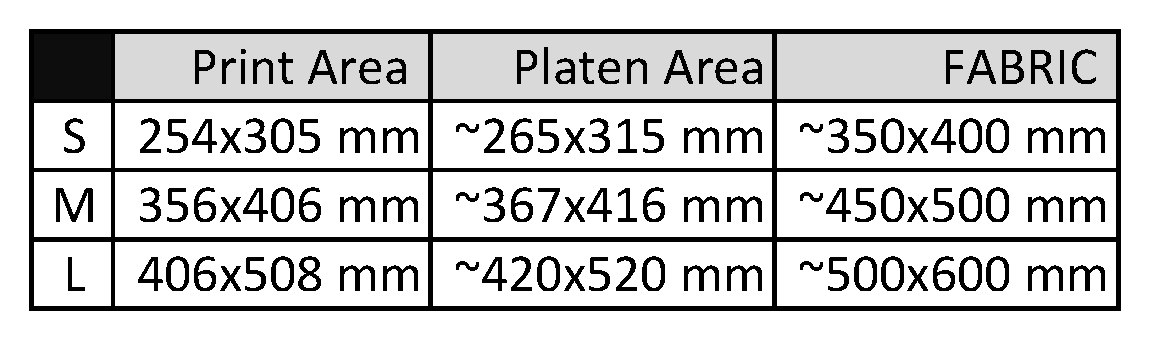

There are three S, M and L printing plate sizes. The following table shows the size of each printing plate (platen area), the printable area (maximum print size), and the dimensions of the fabric required.

File

- TIFF, JPG, PNG tai BMP (JPG is recommended, PNG if needed)

- max 2 GB, 10 million pixels

- RGB, CMYK*, grayscale, binary monochrome

- sRGB (recommendation)

- resolution 90-360 ppi

*) PNG and BMP not supported

Depending on the base material and the design, resolution 90-180 ppi is usually sufficient for the file.

When printing on a dark or colored base fabric, use PNG with a transparent background if you want the background to be same as fabric color.

When printing on a light colored bases (using preset: Light Color T-Shirt), the white color in the file does not print.

Pre-treatment liquids

Light color fabrics:

In some cases, light fabrics may also require a pre-treatment. Such situations may include, for example, spreading the ink on thin silk. Priming also improves the color fastness of the print and increases the brightness of the colors.

Printscorpio's

Tubijet Colorfast 10 pre-treatment liquid can only be used on light color fabrics.

Dark color fabrics:

Applying EPSON pre-treatment liquid (T43R1) improves the color development for the ink when printing with white ink (for dark and black colored fabrics).

Synthetic fibers:

Synthetic fibers are usually hydrophobic and therefore they need pre-treatment.

Applying EPSON pre-treatment liquid (T43R2) improves the color development for the ink when printing on polyester with color or white ink.