OK7 Costume Workshop

Sewing Studio manual

Completion requirements

Learn how to operate and adjust the industrial sewing machines, and learn how to use the steam iron unit. The instruction videos (5) will show you in detail how to operate and adjust the machines. Note: Open the table of contents from the black arrow "Open block drawer" in the upper right corner.

GENERAL INSTRUCTIONS

- Select the machine according to its intended use (see machine descriptions).

- Turn off the machine when changing the bobbin / needle, and when checking the threading.

- Eye and finger protection components cannot be removed.

- The machines are extremely rarely broken. Usually, the problems are caused by issues with threading or the condition of the needle. Be patient and try to solve the problem.

1. Industrial sewing machines

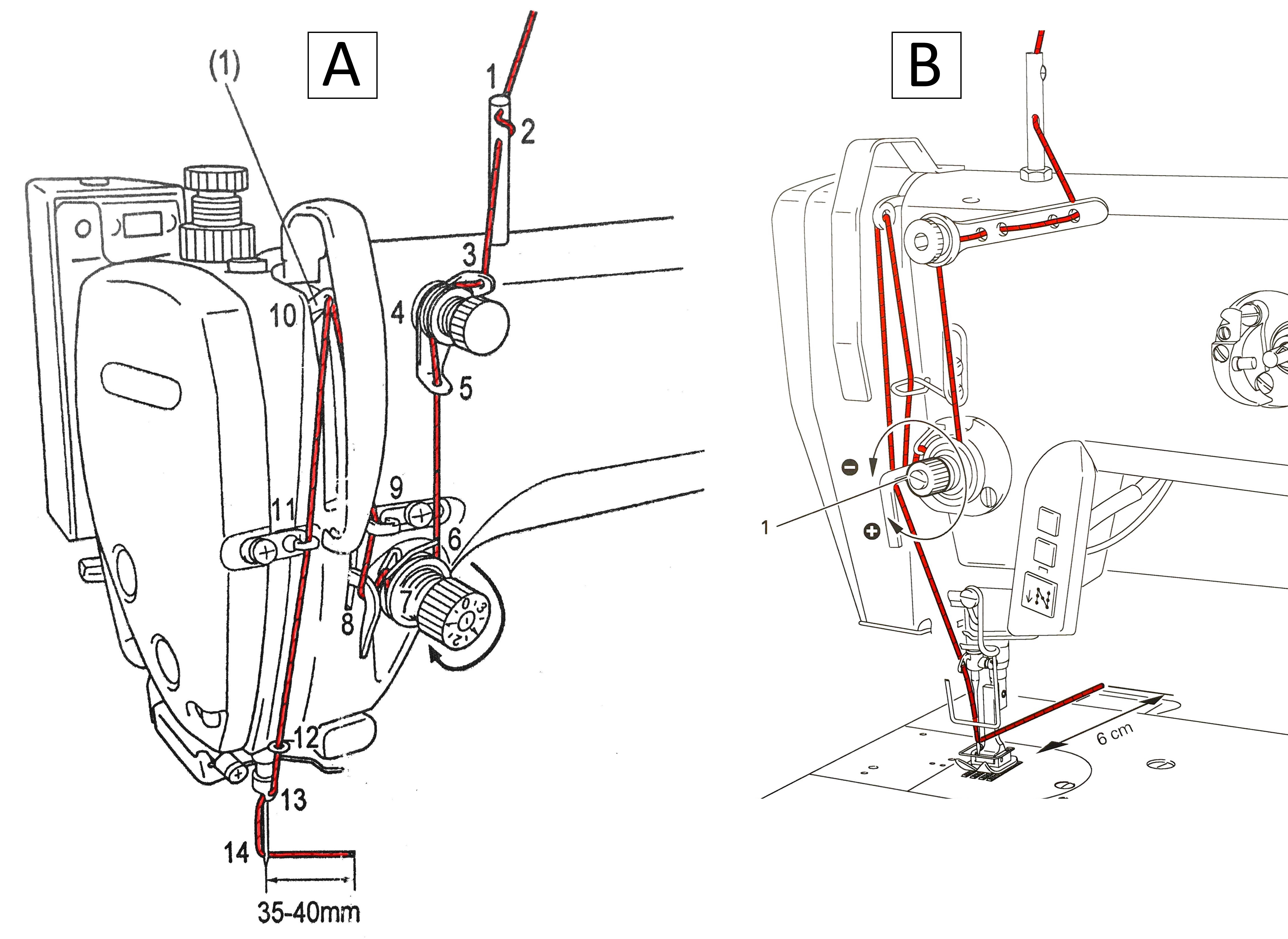

1.3. Threading (video)

The easiest way to change the thread is by pulling the new thread through the machine with the help of the old one

-

Turn off the machine. - Snip off the thread of the old spool at the spool roll and remove the roll.

- Place the new spool in place and tie it to the old thread.

- Lift the presser foot manually, the tension discs are released.

- Pull the thread through.

- Insert the thread through the eye of the needle.

- In straight stitch machines, the needle is threaded from left to right.

- In zigzag machines, the thread goes into the eye of the needle from front to back.

- Check the threading, it is common that the thread remains on top of the tension discs (4 and 7) and not in between, in which case the tension does not work.

- The basic principles of threading are the same for straight stitch machines (A) and for zigzag machines (B), see below.

Thread size

No. 100 - Good for basic sewing.

No. 120- Thinner thread for overlockers.

No.30–80 - Heavy threads for triple feed machines and strong needles.

Crêpe - Thin and slightly stretchy thread for pique machines.